Toro Log Splitters 22618HD 2019 Cylinder and Wedge Assembly Replacement

ID: 139748

Description: This guide shows how to remove and replace the...

Steps:

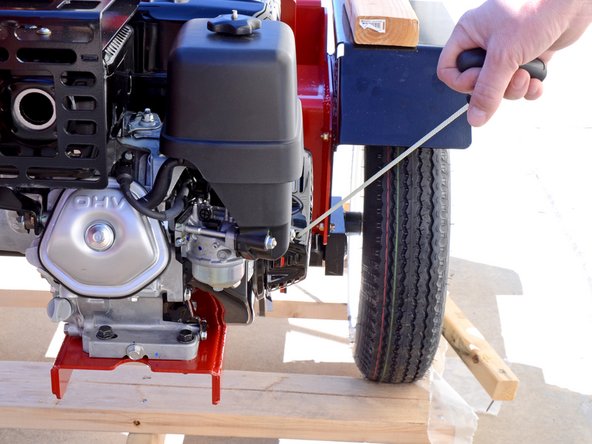

- Flip the red engine ON/OFF switch to the ON position.

- Follow the device's detailed operating and safety procedures before starting the device.

- Pull the motor's pull-start cable to start the motor.

- Push the control valve lever towards the rear of the device to extend the piston and advance the cutting wedge.

- Flip the red engine ON/OFF switch to the OFF position.

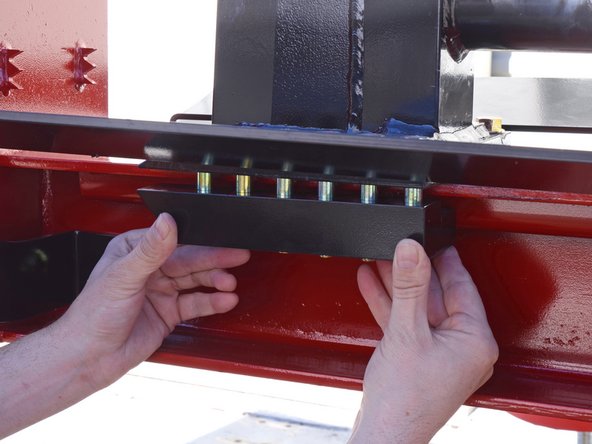

- Use an impact wrench with a 3/4 inch socket to loosen the twelve bolts and twelve nuts securing the slide bars to the underside of the cutting wedge.

- If an impact wrench struggles to remove these bolts, a breaker bar may be necessary.

- Remove the left slide bar.

- Remove the right slide bar.

- Remove all twelve 3/4 inch bolts from the cutting wedge.

- Flip the red engine ON/OFF switch to the ON position.

- Pull the motor's pull-start cable to start the motor.

- Use the control valve lever to retract the cutting wedge until it is seated underneath the dislodger bracket.

- Retracting the cutting head reduces the amount of hydraulic fluid inside the cylinder, resulting in less spillage.

- Residual hydraulic fluid will be trapped in the hoses connected to the cylinder, and will drip out during the following procedure.

- Place a bucket underneath the device, below the cylinder to catch any hydraulic fluid drips.

- Have rags handy to stop drips and clean up affected areas.

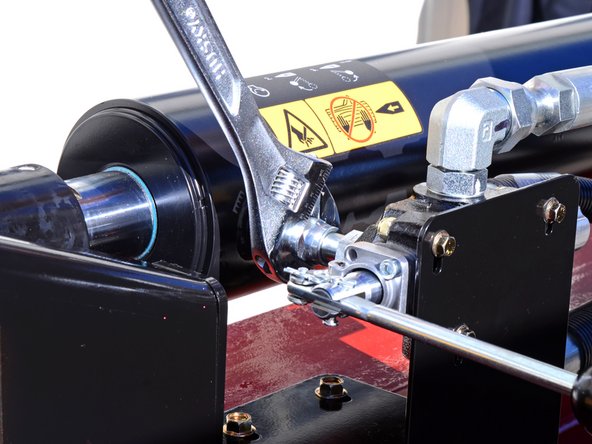

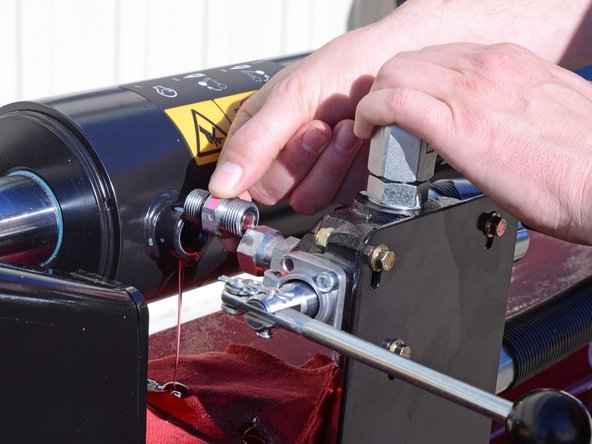

- Use an adjustable wrench to loosen the nut securing the piston extension hose to the L-fitting on the side of the cylinder.

- Remove the piston extension hose from the L-fitting.

- This hose will have excess hydraulic fluid, so tilt it down towards the catch bucket and let the fluid drain out.

- Use an adjustable wrench to loosen the nut securing the L-fitting to the side of the cylinder.

- Use an adjustable wrench on the L-fitting itself to rotate it to a vertical position with the opening facing down.

- This allows excess hydraulic fluid to drip out. Keep a bucket underneath the device to catch drips.

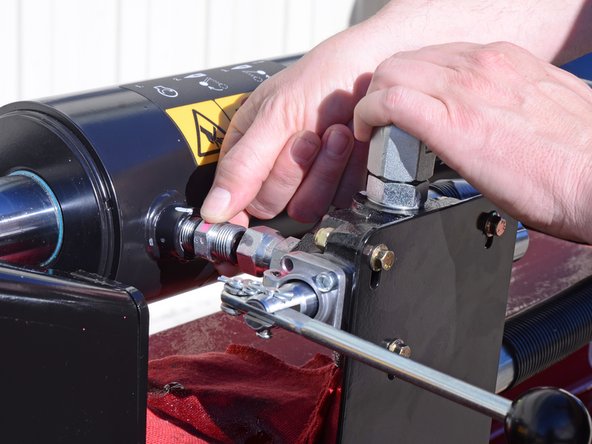

- Use an adjustable wrench to loosen the nut securing the control valve to the fitting on the cylinder.

- Use an adjustable wrench to loosen the fitting on the cylinder.

- Slightly bend the control valve assembly away from the device to create a gap large enough for the fitting to clear.

- Remove the fitting.

- Shim the cylinder with wood blocks to keep it at its resting height, parallel to the frame.

- Pull to remove the two cotter pins securing the large pivot pin.

- Remove the pivot pin.

- The cylinder should now be resting on the wood shims.

- The following steps require two people.

- The cylinder and wedge assembly is extremely heavy, so use caution.

- Shift the cylinder and wedge assembly towards the rear of the device, until it clears the central pin hole.

- Rotate the cylinder until the L-fitting is vertical.

- Support the cylinder and push the assembly towards the rear of the device until it clears the dislodger bracket.

- Remove the cylinder and wedge assembly.