Bosch 70A alternator bearing, commutator contacts replacement

ID: 147213

Description: In order to overhaul the alternator with...

Steps:

- Remove the regulator: two screws (slotted in the original)

- The carbon brushes should still protrude by at least 5 mm, otherwise replace the carbon brushes or the entire regulator. Here they are 12 mm.

- On older alternators, the screws may be rusted solid. Spray generously with rust remover or penetrating oil and allow to soak in for a while if necessary.

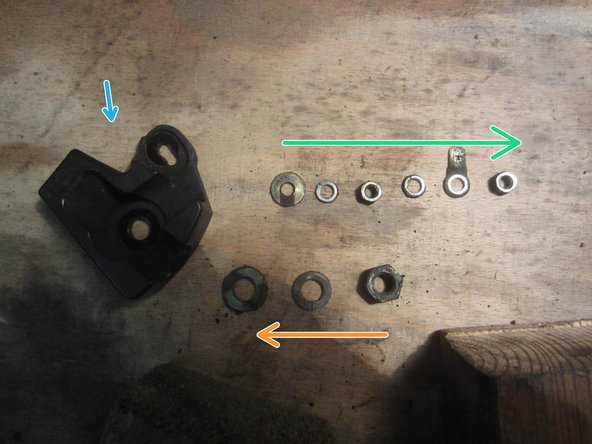

- Unscrew the nuts and washers (if present) on the two/four pull arms.

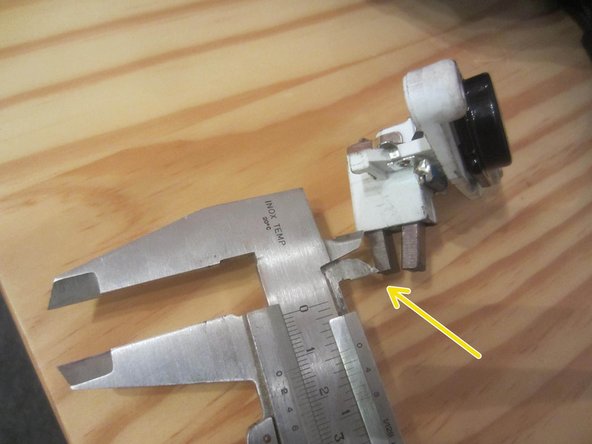

- Unscrew the nuts and washers on the positive contact bolt (13 mm).

- Unscrew the nuts, washers, and contact tongue from the control line (7 mm).

- Unscrew the nuts, washers, and contact tab from the control line (7 mm).

- Unscrew the belt pulley: hold it in place with an old belt and unscrew it with a wrench or ratchet. (22 mm)

- Remove the nut and all washers as well as the fan blade, noting the order.

- Remove the crescent key.

- Mark the alternator housing for later reassembly.

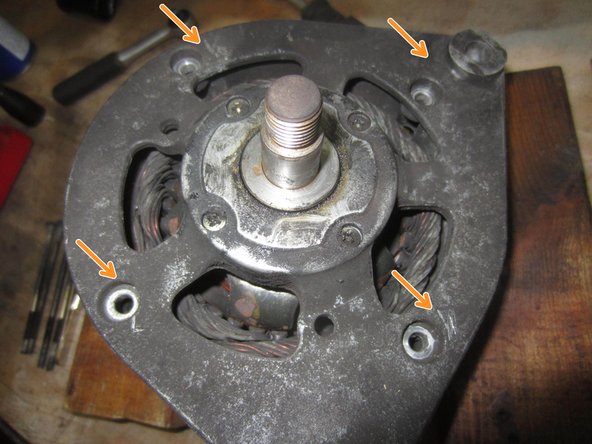

- If the four tie rods (screws) are of different lengths, note or mark where each one belongs

- Unscrew the four screws (PH2).

- Note: There are versions with four screws of the same length and versions with screws of different lengths.

- Pull out the front housing part with the stator, using a plastic hammer to help if necessary.

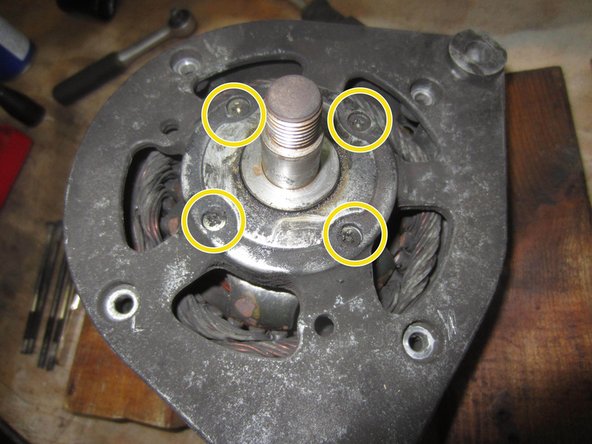

- Remove the four countersunk screws

- Pull the rotor out of the bearing shield (housing).

- Bearing shield and screws

- Check: between the commutator segments 2.8 ohms +/- 10%, no contact with the housing?

- Even if the resistance is correct, the contacts are so worn that the commutator ring must be replaced.

- Wear limit: commutator ring diameter 27.8 +/- 1 mm, max. runout 0.03 mm

- This step is also necessary to replace the commutator ring

- Remove the two bearings from the rotor shaft; a good bearing puller is helpful.

- This step is necessary to check the diodes

- In the rear housing, remove the two screws that connect the diode plate to the housing

- Pull the diode set and stator winding out of the housing

- Do not lose the plastic bushing (or sliding ring).

- Desolder the three stator cables.

- Do not break the cables (e.g. by bending them).

- Solder quickly (short and hot) so as not to fry the rectifier diodes.

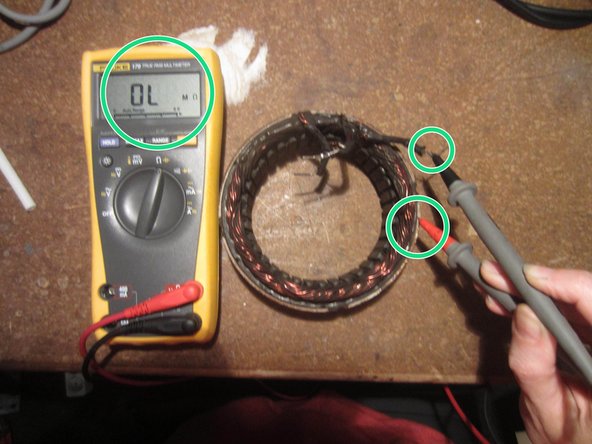

- Check the stator windings for short circuits to ground. Target: infinite resistance

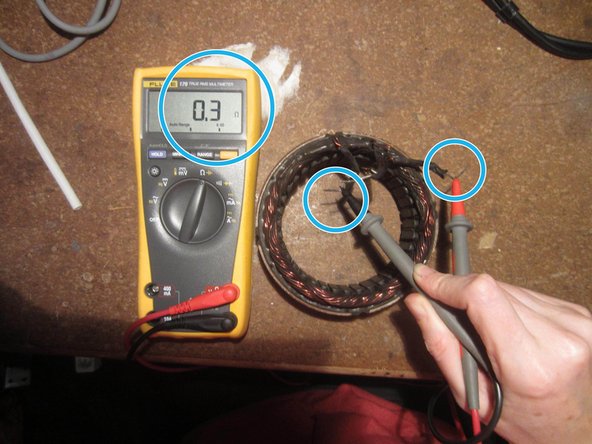

- Check continuity of the stator windings (the displayed 0.3 ohms) are inaccurate but continuity is present

- Theoretically, the resistance of the windings (always 2 phases) can also be checked: should be 0.09 ohms +/-10%. However, this is not possible with a simple multimeter; 0.3 ohms is displayed here.

- Insert translation here