Pentax ZX-5n Mirror Motor Gear Replacement

ID: 153198

Description: A common failure of the Pentax ZX/MZ cameras is...

Steps:

- Push down on the screw to depress the spring loaded hinge and release the door.

- Remove six 5.3 mm #00 screws.

- Remove one 3.4 mm #00 screw.

- The short screw has a machine thread and screws into the plate underneath. The rest screw into the plastic body.

- Remove three 5.3 mm #00 screws (the bottom-most screw is not always present).

- Remove one 7.3 mm #00 screw.

- Remove the remote trigger cover.

- Remove one 3.4 mm #00 screw.

- Remove two 5.3 mm #00 screw.

- Gently lift up on the flash housing to help remove the cover if necessary.

- Remove two 3.9 mm #00 screws.

- Slide the eye cup up and off to access the screws underneath.

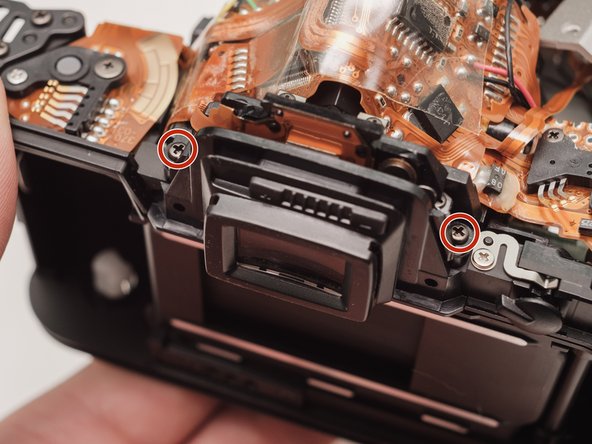

- Remove two 5.3 mm #00 screws by the eyepiece.

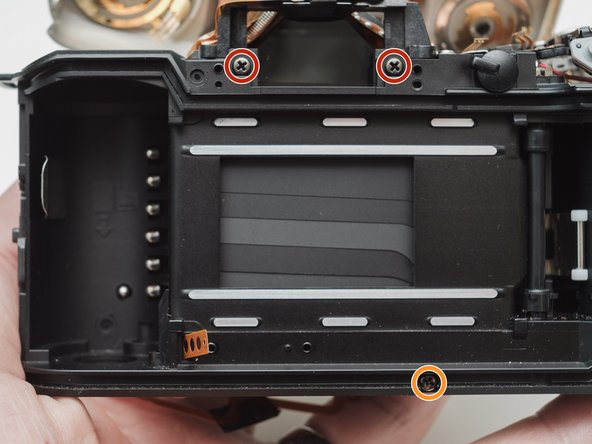

- Remove one 6.8 mm #00 screw in the battery compartment.

- Remove one 7.0 mm #00 screw near the take up spool.

- Lift the cover so it is just free of the body. It is still attached by several wires.

- Use a 1kΩ-10kΩ resistor to discharge the capacitor. Place the resistor between the blue wire, exposed in the previous step, and ground.

- The flash capacitors store energy at a very high voltage. Failing to discharge the capacitors properly could result in personal injury and/or damage to the camera.

- Unsolder one green wire.

- Unsolder one blue wire.

- Unsolder one brown wire.

- Unsolder one black wire.

- Unsolder one black wire.

- Pull black wire out from its routed location.

- Unsolder flex connector

- Be careful not to overheat the flex circuit. Work in short durations. Allow for cool downs in between if necessary.

- Some repairs can be performed with the top cover still connected but the flex connection is fragile and easily damaged.

- De-solder the indicated joints. Use a solder sucker on the tabbed connections.

- Pull the black wire from the battery flex to get more slack in the connection to the top cover.

- Be careful not to overheat the flex circuit. Work in short durations. Allow for cool downs in between if necessary.

- Use a solder sucker to de-solder the four posts from the flex circuit.

- This is the most difficult part of the repair. Patience and persistence are required.

- Be careful not to overheat the flex circuit. Work in short durations. Allow for cool downs in between if necessary.

- Unsolder film advance motor connections.

- Unsolder sprocket counter connections.

- Unsolder power and ground connections.

- Unsolder panorama switch connections.

- Be careful not to overheat the flex circuit. Work in short durations. Allow for cool downs in between if necessary.

- Remove one 4.3 mm #00 screw.

- Gently pry up the plastic carrier under the flex circuit. It may catch slightly on the battery contact tab.

- Pay close attention to the connections around the four through-hole posts as you lift the flex. Make sure that no solder is left over and that it pulls away freely.

- This metal tab is lightly held in place with lacquer and can easily come loose. Keep an eye on it.

- Remove one 3.3mm #00 screw.

- Remove one 3.9 #00 screw.

- De-solder the red wire.

- Peel off the black tape. Leave it attached to the wires.

- Gently peel the flex circuit from the surface of the capacitor.

- There may be additional adhesive underneath the larger capacitor.

- Lift the two capacitors and the flash PCB out as a single unit.

- The double sided tape used to secure the capacitors can be softened with isopropyl alcohol if necessary.

- Remove two 3.4 mm #00 screws. Remove the plate holding the contacts in place.

- Peel tape from the plate. Leave the tape attached to the flex circuit.

- Remove the flex circuits from their retaining studs.

- Remove one 3.3 mm #0 countersunk screw.

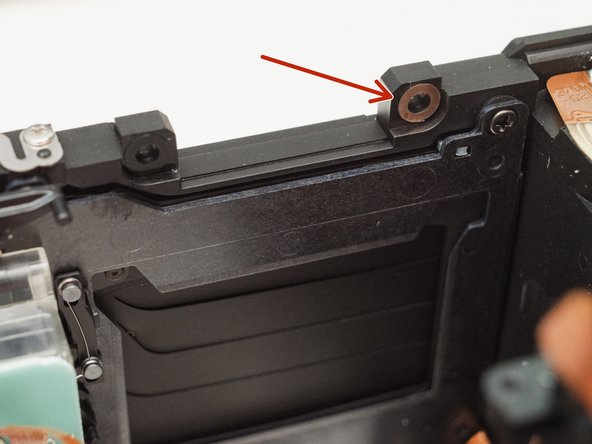

- Remove one 3.9 mm #0 shoulder screw.

- Remove four 3.3 mm #00 screws.

- Pull a little slack through the housing on this flex cable.

- Pop the plate off its posts, rotate slightly clockwise and pull gently through the loosened flex cable.

- To the camera tech that left me a happy little note...I see you.

- It's best to remove these parts now so they don't fall out later on in the repair.

- Remove one 3.8 mm #00 screw.

- De-solder the connections.

- Lift the flex off the retaining studs.

- Be careful not to overheat the flex circuit. Work in short durations. Allow for cool downs in between if necessary.

- Remove two 5.3 mm #0 screws.

- Remove two 7.4 mm #0 screws.

- Remove one 8.3 mm #0 screw.

- Remove one 3.3 mm #00 screw. The metal bracket will be loose and should be removed as well.

- Push the front housing block slightly up then lift the left side up and away from the housing.

- Proceed slowly and watch for any components that are catching. The right side is still attached by a large flex cable.

- There may be shims at the mounting points of the front housing block.

- Note the positions and remove if loose.

- De-solder the black wire.

- Remove four 3.7 mm #00 screws.

- Detach the buzzer from its mounting posts. Use isopropyl alcohol to soften the lacquer if necessary.

- Grab the motor and gently wiggle the plate loose.

- If it feels stuck, move the sliding plate down, towards the bottom of the camera

- De-solder the red and black wires.

- Remove two #00 screws.

- Use the lettering on the motor to note its orientation. If installed or wired backwards, the motor will spin in the wrong direction.

- Pull off the old gear.

- Press the new gear on until about 1 mm of the shaft extends past the end.

- If it is too difficult to press on, use a soldering iron to heat the brass gear. A small amount of thermal expansion should make it easier.

- The green and yellow gears can sometimes slip off their posts while working with the motor.

- Check that the alignment holes are properly synced before installing the mirror motor assembly.

- Aperture set lever spring. Note this part for installation of the mirror motor assembly.

- Disengage latch so the slide bar can move freely.

- Move the slide bar about half way down its total travel.

- Let the latch snap back into place so the slide bar is held in the new position.

- This ensures that the aperture set lever spring couples properly with the slide bar during reassembly.

- Install the mirror motor.

- Place the left side first. Then swing the right side in, coming up and under the spring loaded lens release.

- Rotate the grey gear downward until the mirror is in the charged/down position.

- Push the shutter charge lever upward. You should see the shutter blades move as you do this.

- The second picture shows the shutter in the charged position. It may already be in this position and not need charging.

- Gently place the front assembly block. Work it into place until the back of the block is flush to the back of camera.

- Proceed with the rest of the re-assembly, following the guide in reverse.