Mitsubishi 3000GT Engine Assembly (6G72 DOHC)

ID: 155415

Description: This guide covers the assembly of the...

Steps:

- Clean and inspect all parts, removing paint, rust, gunk, and grit. This is very important for internal components.

- Reusing worn or damaged parts may result engine failure. Your local machine shop or engine builder can usually recondition worn parts rather than replace them.

- Assemble the engine in a clean and dust free work area. Place oiled parts on a lint-free rag to avoid picking up debris from the work surface.

- Use a tap to clean out threads before assembling parts.

- Use a cylinder hone and drill to prepare the cylinder walls. First clean the walls, then lubricate with diesel fuel or engine oil before honing.

- Vary the drill speed and up/down motions to achieve a 30 degree cross hatch pattern on the walls.

- This process removes any glazing and restores the correct surface finish needed for the piston rings to seal.

- Make sure to clean the cylinder walls and remove all grit created by the honing process.

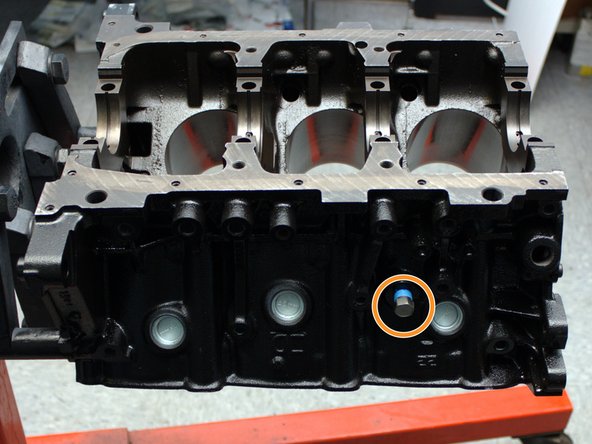

- Install the following expansion plugs using a socket and hammer:

- One 41.5mm plug (right side)

- Two 35mm plugs (rear)

- Five 25mm plugs (left and right sides)

- Install the two threaded hex plugs (front and rear) using an 8mm hex wrench.

- Install the two threaded coolant plugs (left and right side) using a 14mm wrench.

- Apply sealant or pipe tape to the plug threads.

- This step is for turbo engines only.

- Install the six oil squirters into the angled holes in the main bearing journals using a punch and hammer.

- Make sure each oil squirter is fully seated and below the bottom of the oil feed groove.

- Do not install oil squirters in the center oil feed holes.

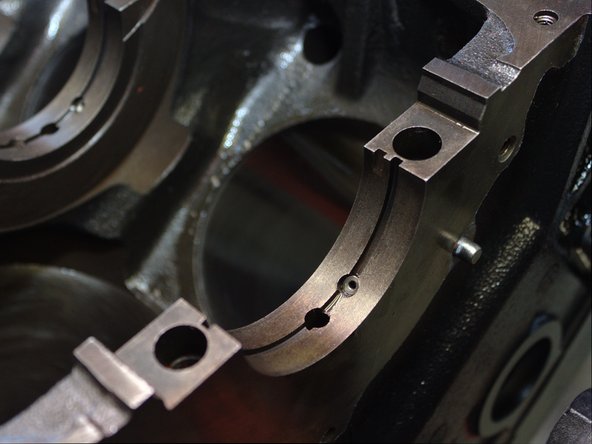

- Install the main bearings into the block and girdle.

- Install the grooved bearings in the block side.

- Make sure the journal surfaces underneath are clean and dry.

- Carefully install the crankshaft into the block.

- Make sure the bearings are clean and dry.

- Do not rotate the crankshaft after it is installed.

- Add a small length of Plastigauge to each bearing journal.

- Carefully set the girdle onto the crankshaft. Line it up perfectly with the bearing journals on the block.

- The girdle fits very tightly into the block and will not be fully seated until the next step.

- Apply engine oil to the main bolt threads and underside of the head.

- Do not dip the bolt in engine oil. Too much oil may damage the block.

- Install the main bolts. Evenly tighten until snug using a socket wrench and 17mm socket.

- Tap the girdle with a soft-faced hammer while continuing to snug the main bolts until the girdle is fully seated.

- Install the main cap bolts and tighten them by hand.

- Two-bolt blocks will have eight bolts total.

- Four-bolt blocks will have 16 bolts total.

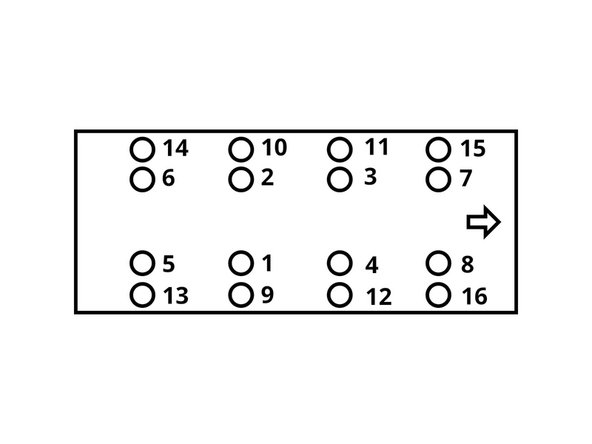

- Use a torque wrench and a 17mm socket to tighten the main bolts to the specified torque:

- Two-bolt blocks: 67 ft-lbs (93 Nm)

- Four-bolt blocks: 54 ft-lbs (74 Nm)

- Tighten bolts in the sequence shown.

- Loosen the main bolts and carefully remove the girdle.

- Measure the width of the Plastigauge to determine the bearing clearance of each journal.

- Main bearing clearance should be 0.0008-0.0020 in (0.020-0.050 mm).

- Do not continue if bearing clearances are out of spec. Double check that the main bearings, crankshaft, and girdle are installed correctly and that the crankshaft isn't excessively worn.

- Remove the crankshaft.

- Apply assembly lube to the smooth side of the thrust washers.

- Stick the thrust washers onto the sides of the #3 journal on both the block and girdle.

- The thrust washer grooves face away from the bearing journals.

- Apply assembly lube or engine oil to the main bearings and thrust washers.

- Reinstall the crankshaft and girdle.

- Be careful not to knock the thrust washers out of position.

- Reinstall the main bolts and repeat Step 8.

- Spin the crankshaft one complete rotation. It should spin smoothly throughout.

- Attach a dial indicator to the nose of the crankshaft to measure end play.

- Use a large flathead screwdriver to carefully move the crankshaft side to side. Zero the indicator at one extreme, then take a measurement at the other extreme.

- Crankshaft end play should be 0.0020-0.0098 in (0.050-0.250 mm).

- Do not continue if the end play is out of spec. Double check that the thrust washers are installed correctly and of the correct thickness.

- This step is for two-bolt turbo engines only.

- Install the four girdle side stays.

- One stay is shaped differently and goes in the front-right position.

- Install the eight side stay bolts. Apply engine oil to the threads and underneath the bolt head.

- Do not dip the entire bolt in engine oil. This may damage the block.

- Use a 14mm wrench to snug all bolts.

- Use a torque wrench and 14mm socket to tighten the girdle-side bolts, followed by the block-side bolts.

- The torque is 35 ft-lbs (48 Nm).

- Insert wisdom here.

- Insert wisdom here.

- Insert wisdom here.

- Insert wisdom here.

- Install the head gaskets on the cylinder block.

- Install heads onto block, being careful the head gasket stays in position.

- Install head bolts and hand tighten.

- Use a torque wrench to tighten the head bolts in three even steps:

- N/A Engines: 26, 52, 80 ft-lbs (36, 72, 110 Nm)

- Turbo Engines: 30, 60, 90 ft-lbs (41, 82, 125 Nm)

- Tighten all bolts to the specified torque before increasing to the next torque step.

- Tighten bolts in the sequence shown.