How To Repair a Faulty Switch on a Trio-60 Keyboard

ID: 161028

Description: If your Percent Studio Trio-60 mechanical...

Steps:

- Unplug the keyboard

- Use a keycap puller to remove the keycaps "3", "4", "0'", "-", "Caps Lock", "enter" and both "alt" keys to gain access to screws.

- Place the keycap puller straight over the keycap, so that the wires are under the keycap and pull straight up.

- It may require slight angling and pressure to remove the keycap.

- Remove six 4.0 mm screws with a Phillips #0 screwdriver.

- Consider using a magnetized screwdriver or magnet to remove screws, or leave them in the chassis.

- Remove the top chassis (metal cover) by lifting straight up and off of the keyboard.

- Gently flip the plate and PCB towards the back of the case, so that it lies upside down behind the case.

- Ensure not to pull on or twist the keyboard as it's attached to a cable and could cause damage.

- Use your fingers or a spudger to remove the JST cable on the end of the circuit board.

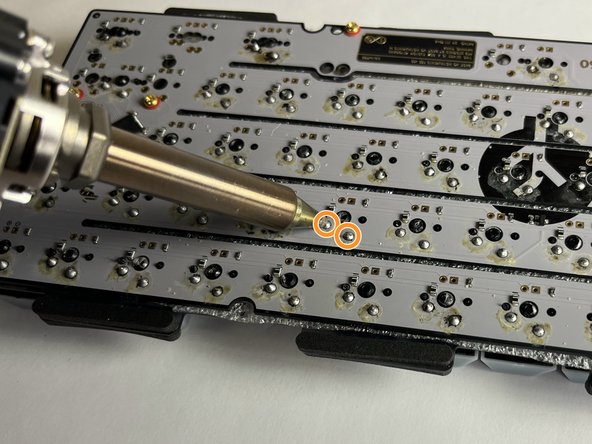

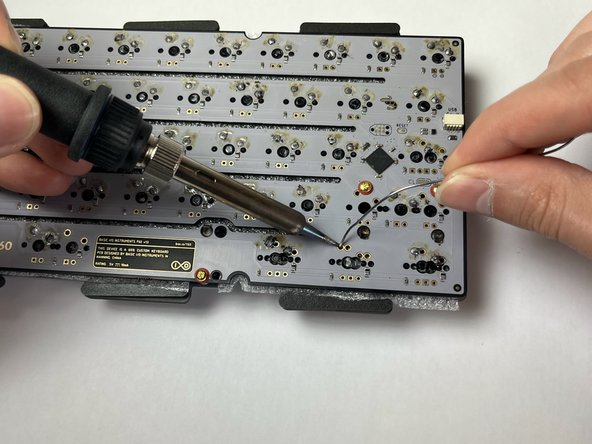

- Make sure to desolder in a well-ventilated area, as the smoke released from the boiling flux is toxic. Placing a small fan near and facing away from your soldering area is recommended.

- Heat the solder until it appears liquified.

- Use your preferred sucking tool of choice to remove the solder (an electric desolder is recommended).

- Desolder both points for each switch you are removing.

- The location of desoldering may vary depending on which switches are faulty.

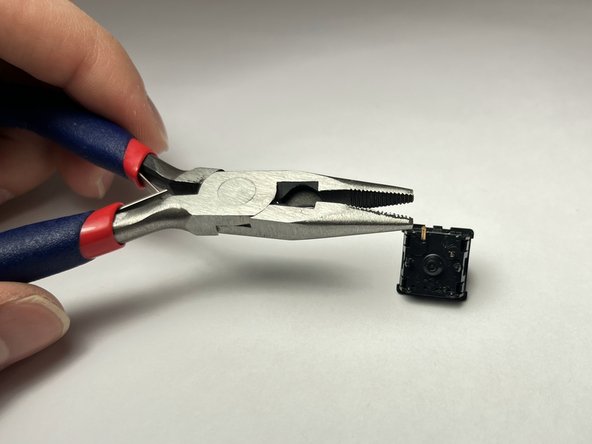

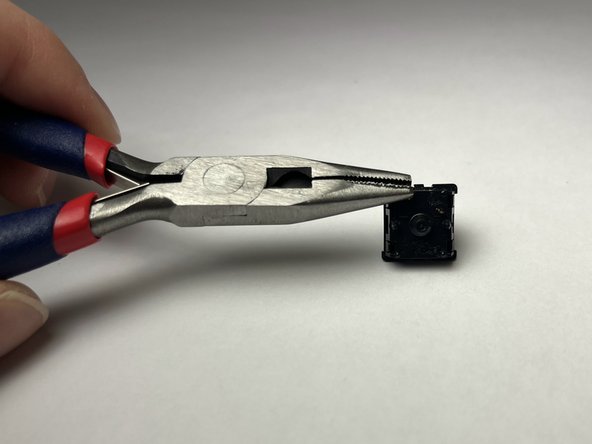

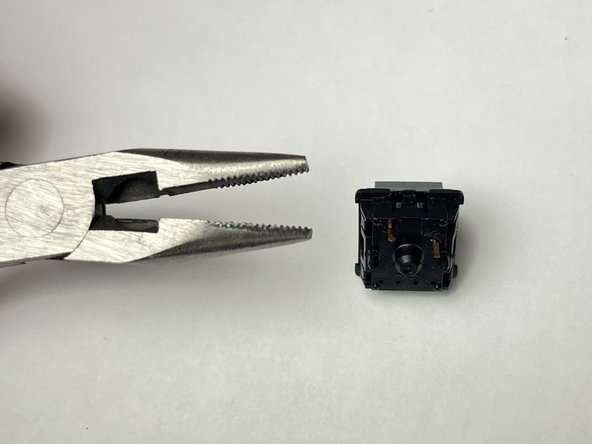

- Use a switch puller or your fingers to remove the faulty switch.

- If a pin is bent, flatten it with pliers so that it is perpendicular to the switch.

- If the pin is not bent, there may be electronic issues causing switch malfunction that will not be covered in this guide.

- Place the new or repaired switch straight down until it is firmly locked into plate.

- Solder the switch and test the keyboard to ensure it functions correctly.

- Make sure to solder in a well-ventilated area, as the smoke released from the boiling flux is toxic. Placing a small fan near and facing away from your soldering area is recommended.

- Optionally apply isopropyl alcohol to Q-tip and clean flux residue from solder joints.