Kobo Clara Colour Motherboard Disconnection (Screen)

ID: 170874

Description: Prereq for disconnecting the motherboard for...

Steps:

- Lay your eReader down so the back cover is facing up.

- Insert the flat edge of an opening pick between the frame and the bottom left corner of the back cover.

- Push the pick downwards at a slight angle until it slides under the back cover.

- Slide the pick toward the bottom right corner to release the clips along the bottom edge.

- Remove the pick and reinsert it under the bottom left corner.

- Angle the pick flat under the back cover and rotate it around the bottom left corner to release its clips.

- If you're having trouble, try twisting the pick to lift the corner clips out of their slots.

- Slide the pick toward the top left corner to release the clips along the left edge.

- At this point, you should be able to grip the back cover and release its remaining clips. If not, slide a pick under the perimeter of the back cover until you can grip an edge.

- Grip the left edge of the back cover and lift it away from the eReader to release the remaining clips.

- Remove the back cover.

- During reassembly, align the back cover over the eReader and press along the perimeter until all its clips snap back into place.

- The entire surface of the eReader's internals is covered in a thin, plastic-like waterproof coating. Keep the following in mind as you continue disassembly:

- While this won't hurt your device, removing the coating compromises the device to potential water damage.

- The coating is brittle and can flake into many small pieces. Heating the coating helps, but working with it is still a time-consuming process.

- The ZIF connector locking tabs are coated in a gel that can jam the hinge and keep the locking tab from completely unlocking. Make sure the tabs are completely upright before disconnecting any cables.

- Depending on your repair, you might have to remove the coating from ZIF connectors and their cables.

- Heat an iOpener and lay it on the battery connector for 90 seconds to soften the coating.

- Alternatively, you can use a hair dryer or a heat gun.

- Use the tip of a spudger to scrape up the coating along the white battery connector head—enough so you can grab clumps of it with pointed tweezers.

- Use pointed tweezers to peel off all of the coating around the battery connector head and its socket.

- If the coating becomes too brittle and hard to peel off, reheat the connector and try again.

- This is a meticulous process! Failure to remove enough of the coating could damage the plastic head during disconnection, so take your time!

- Insert the point of a spudger under the edge of the battery connector head opposite of the cable.

- There's a surface-mounted component close to the connector. Be careful not to touch it with your spudger!

- Lift up the connector with the spudger to separate the rest of the coating and disconnect the battery.

- During reassembly:

- Inspect the connector head and its socket for any remaining coating that could prevent a good connection.

- Peel off the coating, heating the area when the coating becomes too brittle.

- It doesn't have to look pretty! You just need to remove enough coating so the connector head sits properly in its socket.

- When working on or near the battery, don't use sharp metal tools to avoid puncturing and shorting the battery! A punctured battery can leak dangerous chemicals and catch fire.

- If your battery comes with stretch release adhesive, follow the next two steps to remove them.

- Otherwise, skip ahead three steps to remove the normal adhesive.

- The next two steps show how to remove a battery that's secured by stretch release adhesive.

- Use tweezers to pull on the battery adhesive strip's pull tab until you can grip it with your fingers.

- While holding the battery in place, pull the strip out slowly and steadily at a low angle. Give it plenty of time to stretch and un-stick from under the battery.

- You can also wrap the adhesive strip around a spudger and "roll" it for a more consistent pull.

- If the adhesive strip breaks off, try to retrieve it using your fingers and continue pulling—but don’t pry under the battery.

- If you can't retrieve a strip, don't worry! Remove as much adhesive as possible and skip down two steps for an alternate method.

- Lift the battery out of the frame and remove it.

- If you're transferring the battery to a new screen, inspect the battery for any dents or deformations.

- Never reuse a damaged battery! If your battery shows any signs of damage, replace it with a new one.

- During reassembly, follow this guide to install a new battery or to transfer an old battery to a new screen.

- The next four steps show how to remove a battery that's secured by regular adhesive.

- Apply a few drops of isopropyl alcohol under the right edge of the battery.

- Tilt the eReader up to let the isopropyl alcohol flow under the battery and wait one minute for it to soften the adhesive.

- Slide a plastic card a half an inch (~13 mm) under the top right corner of the battery.

- Rotate the plastic card so its short edge sits under the right edge of the battery.

- Slide the plastic card under the battery to separate the adhesive and the thin layer of coating.

- Don't bend or crease the battery! Avoid prying or lifting up with the plastic card.

- If you're having trouble, apply a few more drops of isopropyl alcohol and try again.

- Lift the battery off the frame and remove it.

- If you're transferring the battery to a new screen, inspect the battery for any dents or deformations.

- Never reuse a damaged battery! If your battery shows any signs of damage, replace it with a new one.

- During reassembly, follow this guide to install a new battery or to transfer an old battery to a new screen.

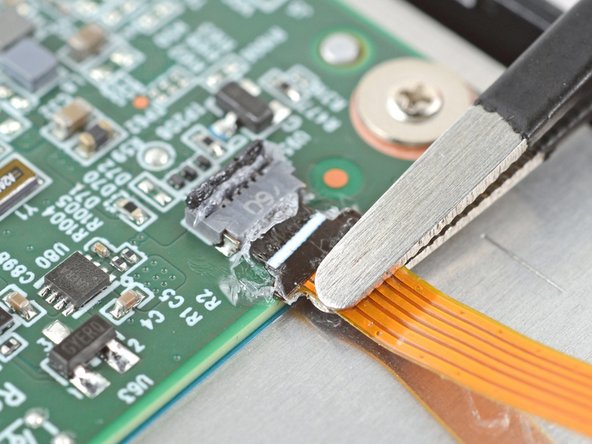

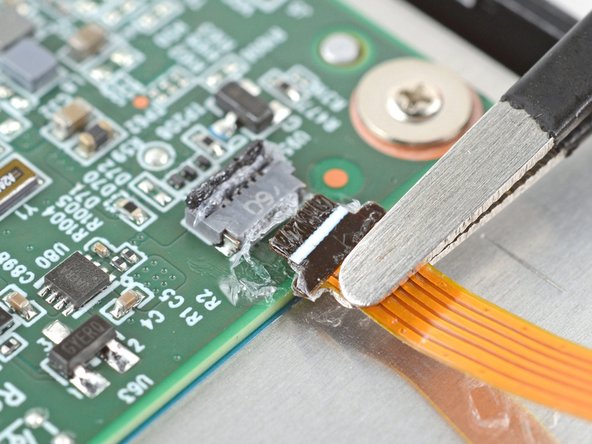

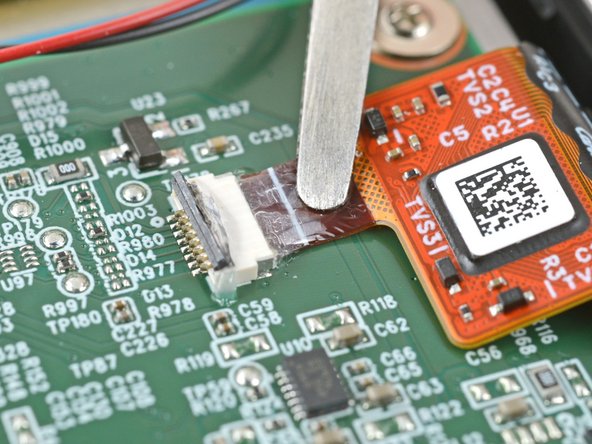

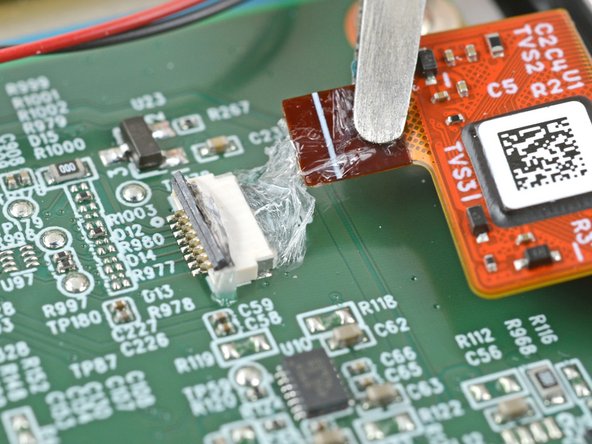

- There are surface-mounted components next to the power button ZIF connector. Follow the instructions carefully to avoid dislodging them.

- Insert the tip of a spudger under the right side of the power button ZIF connector's black locking tab.

- Lift up the locking tab with the spudger to unlock it.

- The locking tab should be nearly vertical when unlocked. If not, gently push the tab forward to compress the gel and completely unlock the tab.

- Heat an iOpener and lay it on the power button connector for 90 seconds to soften the coating.

- Alternatively, you can use a hair dryer or a heat gun.

- Use blunt nose tweezers to grip the cable close to the head and pull it away from its ZIF connector slowly and steadily to separate the coating.

- If the coating feels stubborn, reheat the connector and try again.

- Gripping the tweezers closer to the tip can help you get a tighter hold on the cable.

- Keep pulling on the cable until the cable comes completely out of its socket.

- During reassembly:

- Inspect the head of the cable and the ZIF connector for any remaining coating that could prevent a good connection.

- Peel off the coating—heating the cable and the ZIF connector when the coating becomes too brittle.

- It doesn't have to look pretty! You just need to remove enough coating to have the cable sit properly in its connector.

- Heat an iOpener and lay it on the power button board for 90 seconds to soften the coating.

- Alternatively, you can use a hair dryer or a heat gun.

- Peel off the coating along one of the long edges of the power button board.

- The side doesn't matter! Choose whichever side has the easiest-to-remove coating.

- Use the tip of a spudger to scrape the coating along the base of the power button board—enough so you can grab clumps of it with tweezers.

- Don't use tweezers to scrape the coating, as you could accidentally puncture the board.

- Use tweezers to peel off the coating on the power button board.

- If the coating becomes too brittle and hard to peel off, reheat the board and try again.

- It doesn't have to look pretty! You just need to remove enough coating so the board can move freely during the next four steps.

- The adhesive securing the power button board is strong and requires time and patience to separate properly. Follow the next four steps closely to avoid damaging the power button board.

- Heat an iOpener and lay it on the power button board for 90 seconds to soften the adhesive.

- Alternatively, you can use a hair dryer or a heat gun.

- Insert an arm of pointed tweezers under the edge of the power button board that you separated the coating from.

- If you're having trouble, reheat the board and try again.

- Slide the arm along the edge of the board to separate enough adhesive to fit an opening pick under the board.

- Keep the arm as flat to the frame as possible to avoid scratching the metal.

- Remove the tweezers and immediately replace it with the tip of an opening pick to prevent the adhesive from resealing.

- Slide the pick along the edge of the power button board to separate the adhesive.

- Rotate the opening pick under the bottom of the power button board and under its cable.

- Slide the opening pick along the other edge of the board to separate the remaining adhesive.

- Pull the power button board off the frame and remove it.

- During reassembly, follow this guide to transfer your power button board to a new screen or to install a new one.

- Use the flat end of a spudger to lift up the locking tab on the digitizer cable ZIF connector.

- The locking tab should be nearly vertical when unlocked. If not, gently push the tab forward to compress the gel and completely unlock the tab.

- Apply a heated iOpener to the digitizer cable ZIF connector for 90 seconds to soften the coating.

- Alternatively, you can use a hair dryer or a heat gun.

- Grip the digitizer cable close to the head and pull it away from its ZIF connector slowly and steadily to separate the coating.

- If the coating feels stubborn, reheat the connector and try again.

- Keep pulling on the cable until it comes completely out of its socket.

- During reassembly:

- Inspect the head of the cable and the ZIF connector for any remaining coating that could prevent a good connection.

- Peel off the coating—heating the cable and the ZIF connector when the coating becomes too brittle.

- It doesn't have to look pretty! You just need to remove enough coating to have the cable sit properly in its connector.

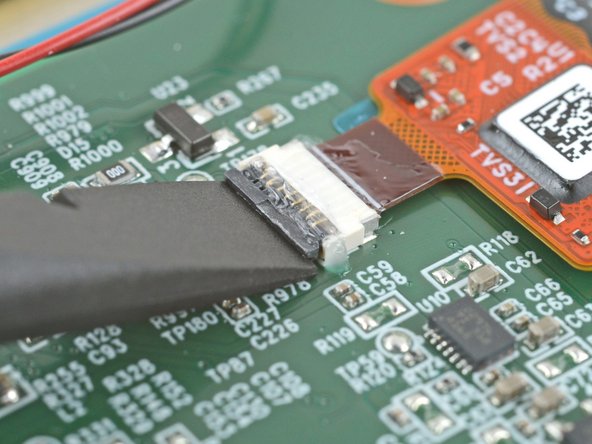

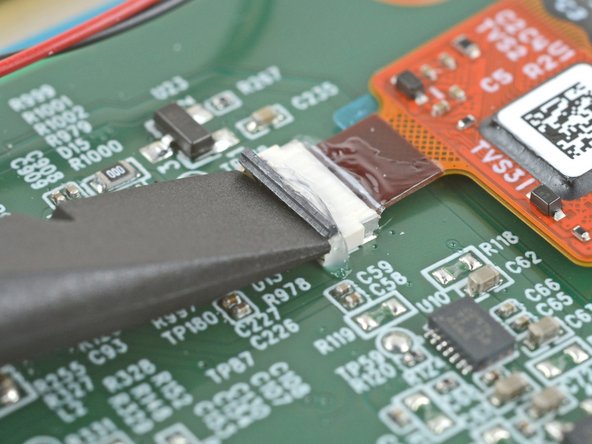

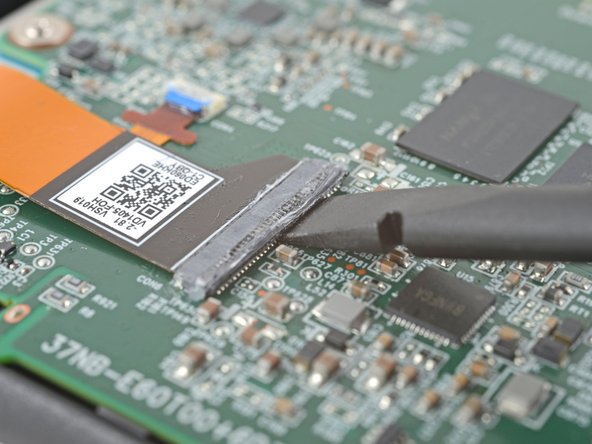

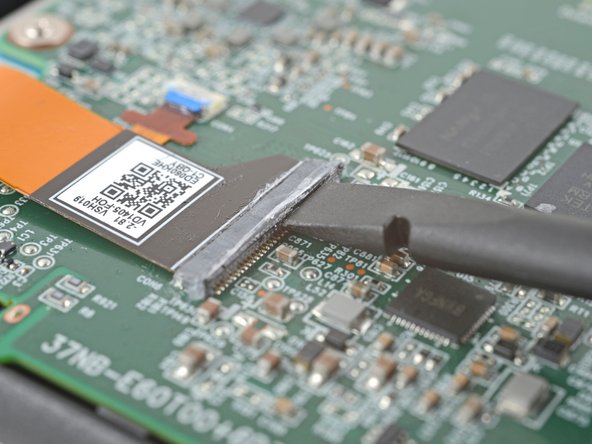

- There are surface-mounted components next to the display ZIF connector. Follow the instructions carefully to avoid dislodging them.

- Insert the flat end of a spudger under the right side of the ZIF connector's black locking tab.

- Lift up the locking tab with the spudger to unlock it.

- The locking tab should be nearly vertical when unlocked. If not, gently push the tab forward to compress the gel and completely unlock the tab.

- Apply a heated iOpener and lay it on the display connector for 90 seconds to soften the coating.

- Alternatively, you can use a hair dryer or a heat gun.

- Use blunt nose tweezers to grip the corner of the display cable closest to the charging port.

- Pull the cable away from the ZIF connector slowly and steadily at a level angle to separate the coating at the corner.

- If you're having trouble, try rocking the cable side-to-side while pulling.

- Gripping the tweezers closer to the tip can help with getting a tighter hold on the cable.

- Repeat the previous step for the other corner until the the cable comes completely out of its socket.

- Lift up the display cable and peel off any remaining coating holding it to the motherboard.

- During reassembly:

- Inspect the ends of the cable and the ZIF connectors for any remaining coating that could prevent a good connection.

- Peel off the coating—heating the cable and the ZIF connector when the coating becomes too brittle.

- It doesn't have to look pretty! You just need to remove enough coating to have the cable sit properly in the connector.

- Lift the display cable out of the way of the backlight cable underneath.

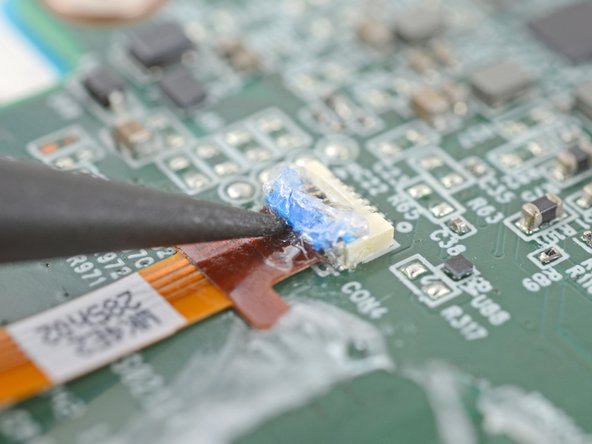

- Use the point of a spudger to lift up the blue locking tab on the backlight cable ZIF connector.

- The locking tab should be nearly vertical when unlocked. If not, gently push the tab forward to compress the gel and completely unlock the tab.

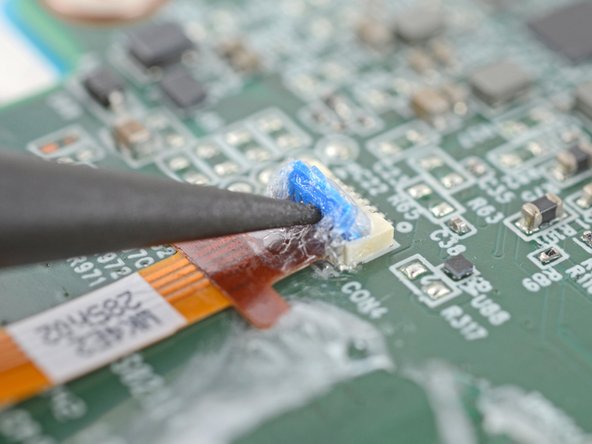

- Apply a heated iOpener and lay it on the backlight connector for 90 seconds to soften the coating.

- Alternatively, you can use a hair dryer or a heat gun.

- Use blunt nose tweezers to grip the cable close to the head and pull it away from its ZIF connector slowly and steadily to separate the coating.

- If the coating feels stubborn, reheat the connector and try again.

- Keep pulling on the cable until it comes completely out of its socket.

- During reassembly:

- Inspect the head of the cable and the ZIF connector for any remaining coating that could prevent a good connection.

- Peel off the coating—heating the cable and the ZIF connector when the coating becomes too brittle.

- It doesn't have to look pretty! You just need to remove enough coating to have the cable sit properly in its connector.