Microbot Push Teardown

ID: 72598

Description: A few months ago, we pre-ordered the MicroBot...

Steps:

- Removing the 4 Torx screws and 1 regular one beneath the black rubber pad shows us a gearbox, 2 PCBs and a battery

- According to its specs, the MicroBot has a battery life of about one year. The battery is rechargeable, using a regular 5V charger with a micro USB connector.

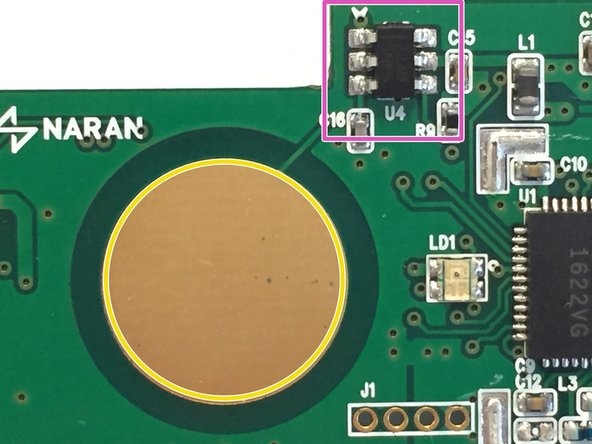

- Battery charging circuit

- Charging IC

- Transistor to control the red and green LEDS next to the USB port, indicating whether or not the battery is fully charged

- Battery protection circuit

- These types of ICs are used to “sense” the current

- When the specified current limit has been reached they trigger a switch that will break the current path to the battery. The switch that is triggered in this case is a Dual N-Channel Enhancement Mode Power MOSFET, in this case the 8205A

- The capacitive touch button and matching circuitry (marked in red)

- The big gold circle you see in the middle of the PCB is a capacitive touch button. It’s simply an exposed piece of copper

- The TTP223B chip, this chip is a one-key touch pad detector that can detect the touch of a human finger on the touch pad. It does this by using the “Frequency Change” method

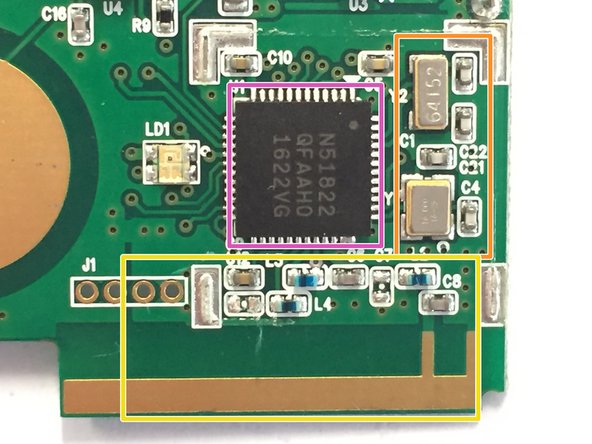

- The bluetooth chip and antenna (I had to remove a metal shield to reveal the chip;)

- The bluetooth chip, in this case the nRF51822 Nordic Semiconductors (It’s a 2.4GHz ultra low-power bluetooth chip built around a 32-bit ARM® Cortex™ M0 CPU)

- To the right of the nRF51822, you can see two oscillators, one 16MHz and one 32.768kHz (marked in orange), which generate the clock waveforms for the CPU

- On the bottom (marked in yellow) you see the antenna circuitry and the PCB antenna itself. As you can see, they did not use a balun chip, but instead created a matching network using some capacitors and inductors.

- This circuit is located on the back of the PCB

- I could not trace back the datasheets of the actual components used, but after probing the upper IC with an oscilloscope I noticed that this is also a voltage regulator. This one boosts the voltage from 2.5 volts back to 4 volts to power the motor and the motor controller

- Motor driver

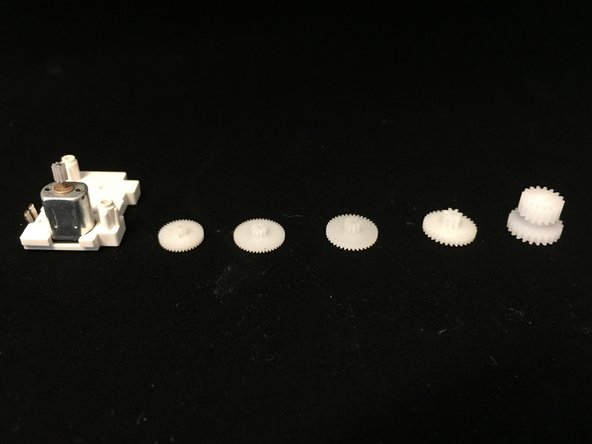

- Opening up the gearbox was fairly simple: I just had to remove two screws to expose the gears and the motor

- If we count all teeth of the gears we come up with a speed reduction of 948.41