Barreto Tillers E1320HTRLR 2016 Tine Drive Motor Bearing Replacement

ID: 140140

Description: This guide shows how to remove and replace the...

Steps:

- Before you begin, ensure that the engine is powered down and cool to the touch.

- Grab the plastic housing at the end of the spark plug wire and pull firmly to disconnect it.

- Flip the red engine ON/OFF switch to the OFF position.

- Flip the fuel valve lever to the OFF position.

- Flip the ignition switch to the OFF position.

- Ensure the wheel drive control lever is set to the neutral position.

- Pull the locking pin out and rotate it 90˚ to unlock the right wheel from the hub.

- Repeat for the left wheel.

- Insert wheel chocks underneath each wheel to keep the device stationary during disassembly.

- Use an 8 mm socket to remove the outboard bearing grease fitting.

- Use a 9/16 inch socket to remove the four bolts securing the tine shaft to the side plate.

- Use a 9/16 socket and wrench to remove the five bolts and accompanying nuts securing the side plate to the frame, three on the outside and two in the wheel well.

- Tilt the tiller up so the motor side is resting on the work surface with the tines raised.

- Use a 1/2 inch socket and wrench to remove the four bolts and accompanying nuts securing the side plate to the tine cover.

- Slide the side plate down and away from the device to remove it.

- The tines closest to the tine drive motor need to be removed in order to allow access to the bolts securing the tine shaft to the hub.

- Use a 5/8 inch socket with an 11/16 inch wrench to loosen the two 5/8 inch bolts and two 11/16 inch nuts securing the tine to the tine shaft.

- Remove the two tine nuts.

- Remove the two bolts holding the tine to the tine shaft.

- Remove the tine.

- Repeat this procedure for all four tines closest to the tine drive motor, opposite the outboard bearing assembly.

- Keep track of each tine's orientation.

- Use a 5/8 inch socket with an 11/16 inch wrench to remove the two 5/8 inch bolts and two 11/16 inch nuts behind each removed tine.

- Repeat this for each of the four tine locations; there are a total of eight bolts to remove.

- Remove the tine shaft from the hub.

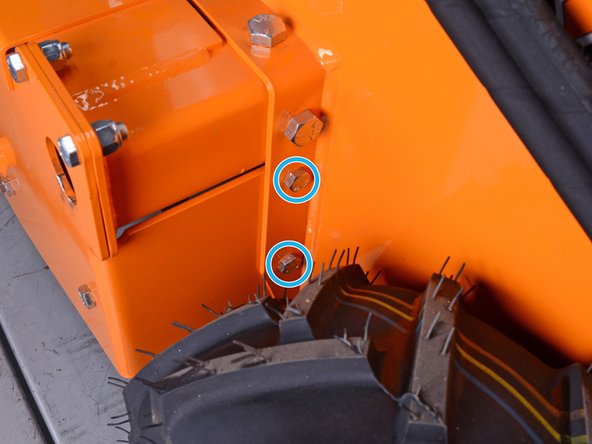

- Use a 3/8 inch hex driver to remove the two cap screws securing the tine drive motor to the lefthand side plate.

- Pull the motor away from the side plate to remove it.

- Use a clean paper towel or shop rag to remove the grease from the tine drive motor bearing.

- Use a pick tool to remove the O-ring from its recess on the outer edge of the tine drive motor.

- During reassembly, install a new O-ring.

- Use a pair of snap ring pliers to remove the inner snap ring from the tine drive motor bearing.

- Use a pair of snap ring pliers to remove the outer snap ring from the tine drive motor bearing.

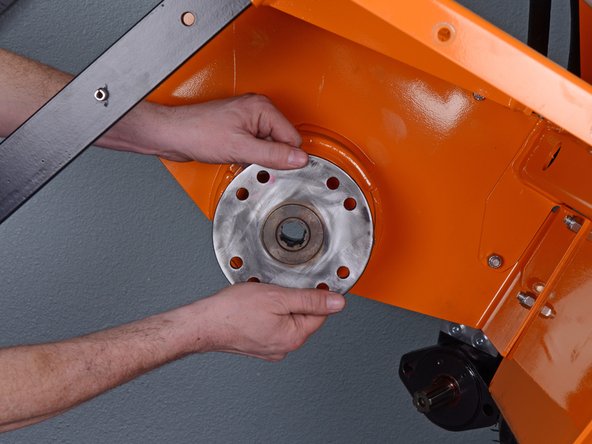

- Remove the tine drive motor hub.

- Use a bearing removal tool to remove the ball bearing from the housing.

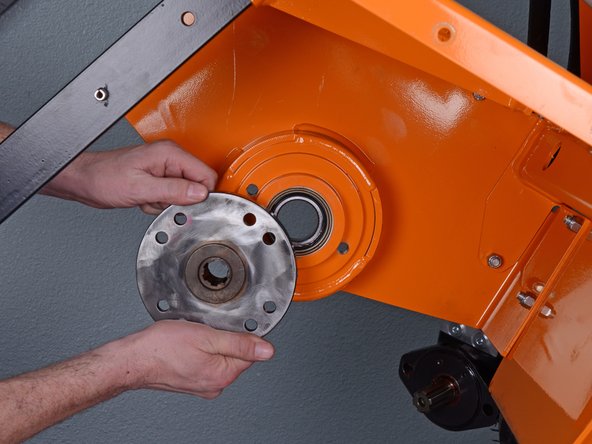

- Grease the internal walls of the outboard bearing housing before installing new bearings.

- During reassembly, ensure the new bearings sit flush along the inner lip of the housing.