Bosch 36618 Drill Driver Teardown

ID: 56493

Description: Overview of how to take apart a Bosch 36618...

Steps:

- Remove the battery before any disassembly.

- Prepare a workspace by having a clean, level surface and any required tools within reach.

- Remove the 11 T10 Torx screws from the exterior of the drill driver.

- The screw circled in orange is recessed quite far and might not be reachable with certain T10 screwdrivers.

- After the 11 exterior screws are removed, pull the plastic housing pieces apart.

- There are no tabs or plastic flaps holding the two pieces together. Pull straight up and the two pieces should separate easily.

- Check out all that dust by the motor, that can't be efficient!

- The second picture is a closer up shot the side with all the electronic goodies.

- The motor and chuck assembly can be pulled up and out.

- Be aware of the speed selector (first picture) which is slotted onto the motor and chuck assembly as you remove it.

- Remove the electrical connections. The colors are marked on the motor so no need to remember which side is which.

- The electrical connections are spade terminals with a little locking piece on the front (non flat) side of the spade. Push the lock to the back and pull the connector straight out.

- What's remaining is the motor and chuck assembly (third picture).

- The chuck can be removed with a hex key, I didn't go that far in the disassembly.

- The motor can be removed from the chuck assembly with a clockwise twist.

- The two red boxes in the first picture depict where the separation will occur.

- The second picture shows the connection on the chuck assembly side.

- The third picture shows the connection on the motor side.

- Remove the black plate on the motor by removing the two T15 Torx screws.

- When reassembling, slotting the gear pictured to the left back into the chuck assembly can be finicky. Be patient and take your time.

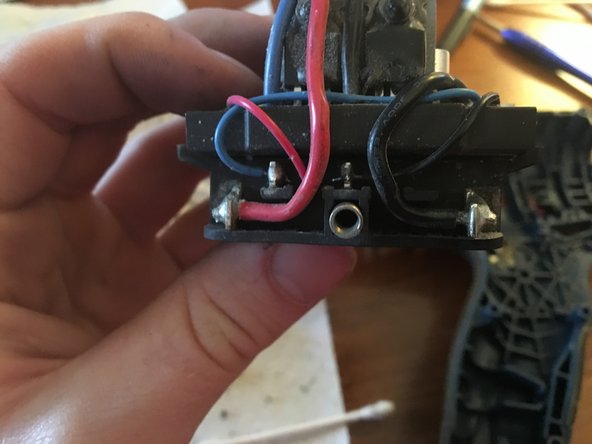

- Here are some closeups of a few electrical connections.

- Picture 1: connections to the trigger assembly.

- Picture 2: connections on the rear of the battery receptacle.

- Picture 1: closeup of the forward, revers, and lockout assembly.

- Picture 2: be cautious of this spring behind the battery receptacle, it likes to fall out.

- Insert wisdom here.

- Here's the thoroughly cleaned and fully reassembled drill. No extra pieces, yay!

- Picture 2. I relabeled the torque ring with Sharpie so that the markings were legible again.

- Look at all that dust and particulates that were gunking up the drill! I'm sure the drill driver will operate more smoother and efficiently now.

- Thanks for looking at my teardown! Happy fixing!